Photograph album of Petrochemicals Ltd.

- Made:

- 1950-1951

- maker:

- Petrochemicals Ltd

The album contains photographs of the construction and equipment of Petrochemicals, the first polystyrene plant at Carrington. Inserted are pieces of paper with captions on.

More

The album size 24 x 34 cms consists of 22 pages containing monochrome photographs.

Page 1. (1) Monochrome photograph size 12 x 19 cms of the 25 gallon pilot plant reactor and receiving vessel. (2) Photograph size 8 x 10 cms the innards of 100 gallon pilot reactor after dispersion has failed. Polymer fills the vessel and cannot be discharged (early 1950). (3) Photograph size 8 x 10 cms, burning off the polystyrene from the choked 100 gallon reactor. Chipping it out proved too slow.

Page 2. Inserted note: Position Jan/Feb. 1950 in the building of the 4,000 ton p.a. Polystyrene plant. (4) Monochrome photograph size 8 x 10 cms building the 4,000 ton p.a. polystyrene plant at Carrington (ca. January 1950). (5) Photograph size 8 x 10 cms, the plant at Carrington (ca. March 1950).

Page 3. Inserted note: Buffer holding vessel being installed. (6) Photograph size 8x 10 cms, building the 4,000 ton p.a. polystyrene plant at Carrington (ca. January 1950). (7) Photograph size 8 x 10 cms, buffer holding vessel being installed.

Page 4. Inserted note: Completed plant at Carrington, 1950. Distillation column at right foreground. (8) Photograph size 18 x 25 cms, completed plant at Carrington, 1950, showing distillation column at right foreground.

Page 5. (9) Photograph size 18 x 25 cms shows the water treatment plant and distillation column to provide pure styrene. Water de-aeration unit is on the right.

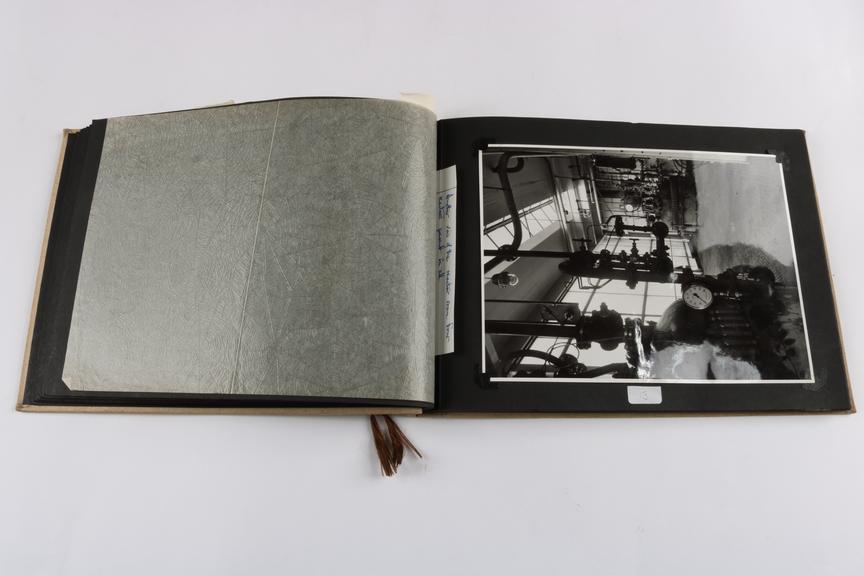

Page 6. (10) Photograph size 18 x 25 cms illustrates the water de-aeration unit. This proved unnecessary.

Page 7. (11) Photograph size 18 x 25 cms shows the top level of the stirred reactors for the dispersion polymerisation of styrene.

Page 8. Inserted note: Instrument panel for the control of the polystyrene plant under automatic running. (12) Photograph size 18 x 25 cms shows the conditioning control desk, reactors in the background.

Page 9. (13) Photograph size 18 x 25 cms shows another view of the reactor room, four reactors were installed.

Page 10. (14) Photograph size 18 x 25 cms shows the instrument panel for the automatic control of the polystyrene plant.

Page 11. (15) Photograph size 18 x 25 cms shows the bottom end of a reactor featuring the main valve, heated dump lines and rotary sieve to deal with oversize beads of polymer.

Page12. (16) Photograph size 18 x 25 cms shows feed lines (glass in foreground) from the buffer vessels to the centrifuge (in the mid ground).

Page 13. (17) Photograph size 18 x 25 cms shows the drying room at rear of the conveyor driers for the polystyrene beads. The tubs on the trolley were used to hoist dry beads to the top of the storage bunkers.

Page 14. (18) Photograph size 18 x 25 cms shows blender with blending hoppers above. Bunker storage feeds via stainless steel containers to a blender enabling poor quality material to be blended to acceptable quality.

Page 15. (19) Photograph size 18 x 25 cms shows polystyrene bead stream running off from main hopper into a vessel for colour mixing. Colour mixer filling from main pearl hoppers.

Page 16. (20) Photograph size 18 x 25 cms shows the dough mixer in operation producing coloured beads. Bead diameters were from 0.2 to 1.0 mm.

Page 17. (21) Photograph size 18 x 25 cms illustrates placing mixer in position in mixing machine.

Page 18. (22) Photograph size 18 x 25 cms. This is the main extruder floor. Pigmented bead mixes are fed into extruders and over corrugated rolls at right and chopped up at left.

Page 19. (23) Photograph size 18 x 25 cms Twin headed extruder feeding coloured polystyrene over corrugated rolls, a corrugated sheet emerging at top left.

Page 20. (24) Photograph size 18 x 25 cms. View of corrugated film of polystyrene from opposite side of the extruder.

Page 21. (25) Photograph size 12 x 17 cms .Show eight members of the management group.

Page 22. (26) Photograph size 18 x 25 cms. Bagging the chopped extruder moulding quality coloured polystyrene from the extruder hoppers.

Page 23. (27) Photograph size 12 x 25 cms. Management group.

Page 24. (28) Photograph size 18 x 25 cms. The quality control laboratory which was situated within the 4,000 ton p.a. plant. This was an unusual location.

Details

- Extent:

-

250

30

340

- Identifier:

- MS/0497

- Access:

- Open Access

- copyright:

-

More

Copies may be supplied in accordance with current copyright legislation and Science Museum Group terms and conditions