Tri-level measurement test (Work Sample no. 10) assessing aptitude for precise measurement and inspection tasks

- Made:

- circa 1980 in Tucson

Tri-level measurement test (Work Sample no. 10) assessing aptitude for precise measurement and inspection tasks, with manual and test sheets, includes case with multiple compartments holding 61 machined parts as well as measuring tools and a diagram of typical flaws, made by Valpar International Corporation, Tucson, Arizona, United States, c. 1980.

This particular test, No. 10, assessed people’s aptitude for precise measurement and inspection tasks. Two administrations of the test were recommended; each one took about 15 minutes. Using a ruler, callipers, a micrometer, and a diagram of typical flaws, evaluees sorted 61 machined parts into 9 bins based on whether the parts fit specifications. Good performance depended on form perception, finger dexterity, manual dexterity, and spatial aptitude. Additionally, the test allowed an observer to assess secondary, work-related characteristics such as the ability to follow instructions, concentration skills, problem conceptualization, and self-confidence.

Details

- Category:

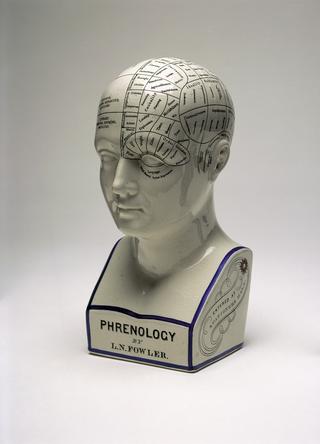

- Psychology, Psychiatry & Anthropometry

- Object Number:

- 2011-101

- Materials:

- plastic (unidentified), particle board, metal (unknown) and paper

- Measurements:

-

overall: 690 mm x 700 mm x 200 mm,

- type:

- measurement test

- credit:

- Department of Work and Pensions