Semi-automatic wire bonding machine for making transistor components, built by Ferranti Electronics at their Gem Mill site, Chadderton, Oldham, 1970-1978.

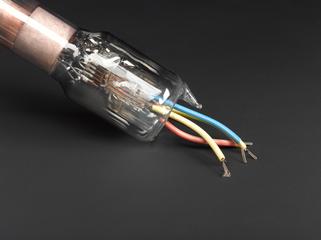

This machine was used for wire bonding transistors which were used in electronics applications including radios, televisions, cars and telephones. The operator, usually female, would use a microscope to sight the point for bonding gold connections between the “dice” or silicon chip and the lead-frame. The device is operated manually by levers underneath the machine.

Up to 90% of the workforce employed at Ferranti’s Gem Mill site were female. They had often previously worked in Oldham’s declining cotton industry, where they had developed transferrable skills operating machinery.

Machines like this were designed and engineered in-house at Gem Mill in the drawing office and the tool room. In the 1950s and 60s, manufacturing semiconductors was a relatively new industry. Ferranti made the first silicon semiconductors (diodes) at Gem Mill in 1955. No equipment for making semiconductors existed at first, it had to be designed and built in-house. As the industry matured, manufacturers saw commercial opportunities in making semiconductor manufacturing equipment and Ferranti ceased making manufacturing tools in-house by the end of the 1980s.