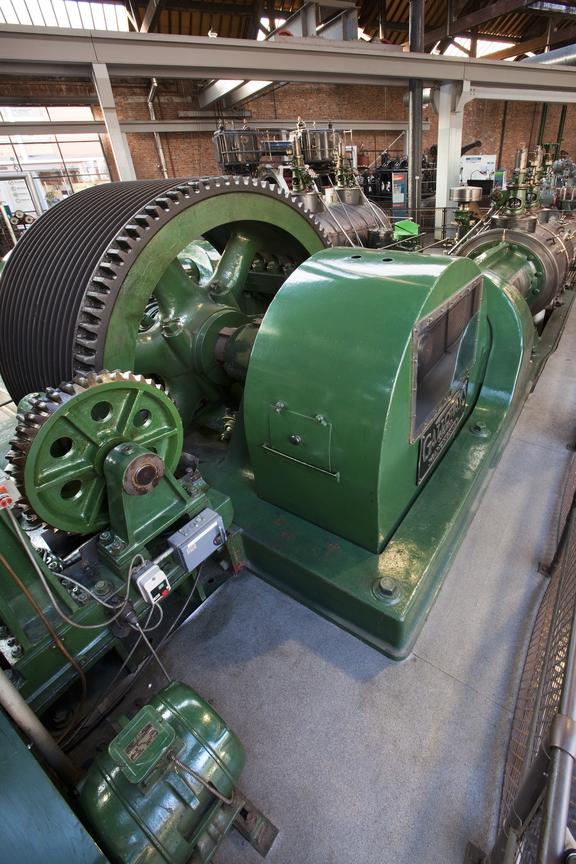

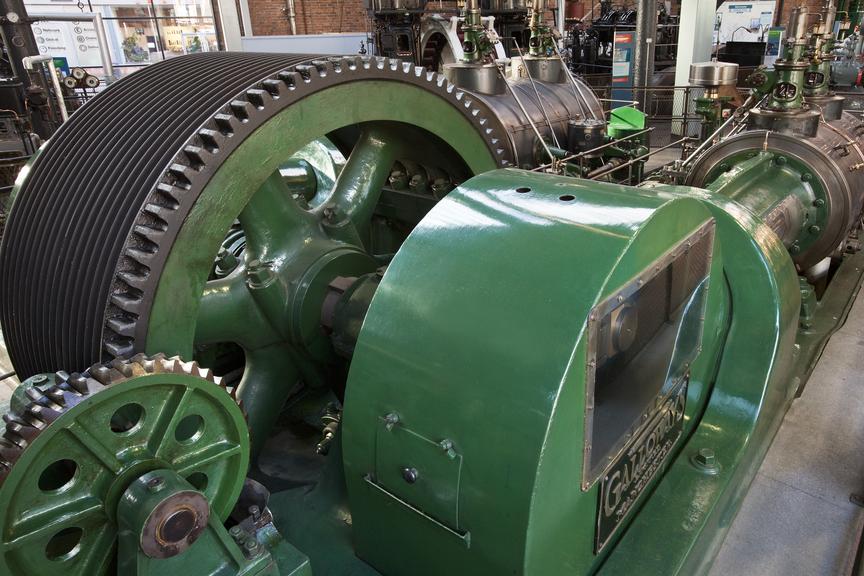

steam engine part; valve from horizontal cross-compound condensing uniflow engine

1926

Horizontal cross-compound condensing uniflow engine, made by Galloways Ltd, Manchester, for Elm Street Mill, Burnley, 1926. Drop-inlet valves, speed 125 rpm, power output 600 horsepower.

Elm Street Mill was a ‘Room and Power’ mill, which means that different companies could hire a space with heating and lighting in the mill and link their machines up to the engine for their power supply. The engine also drove an alternator to generate electricity to light the mill.

From the 1920s, mill owners began to convert from steam power to electric power, with each machine in the mill having its own electric motor. This meant that large steam engines like this were no longer needed for driving machines. Built in 1926, this was the last new reciprocating steam engine to be supplied to a cotton mill and represents the peak of mill engine technology.

This is a uniflow engine. In a uniflow steam engine, steam enters the ends of the cylinder alternately via the drop-inlet valves and passes out through a ring of ports in the middle. This is thermodynamically efficient because there is no alternate heating and cooling of the cylinder ends through steam being also exhausted through them.

The mill owner who installed this cutting-edge engine at Elm Street room and power mill named the two cylinders after his son and grandson. The high pressure cylinder on the left was named ‘Brian’ and the low-pressure cylinder on the right was named ‘David’.