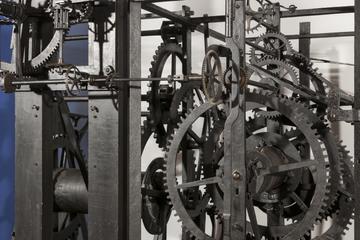

Double dialled longcase clock from Park Green Mill, Macclesfield, made by E. Hartley, Macclesfield, c. 1810, includes clock and belts, pulleys and lineshafting.

Manchester’s mill workers toiled in time with their machines. The new system of textiles manufacturing changed the way they organised their daily lives. Winter or summer, rain or shine, the machines set the pace and the factory clock told them when to work and when to rest.

In the mills, time was money, and some manufacturers tried to control the time in their factories in order to maintain productivity and profits. This double dialled clock from Park Green silk mill in Macclesfield helped mill owners Michael Daintry and John Ryle do this. It was installed in the mill in 1810.

The bottom face of the clock showed the real time. The top face showed ‘mill time’. Its hands were connected to the mill’s water wheel and like the mill's machines, the clock’s hands only moved when the water wheel ran. Each morning, the mill’s engineer set the time on the ‘mill’ clock face to match the actual time, shown on the upper face. If the mill was running properly, the time shown on both faces would match. If the water flowing to the mill’s water wheel stopped or slowed down, so did ‘mill time’. In this way, the production and performance of the mill’s machines, and by that token its workers, could be checked and regulated.

This system did not necessarily work to mill workers’ advantage. If ‘mill time’ ran slow, the mill owner might consider that their employees were not working as hard, and expect them to make up lost production time, working on until the clock showed the correct stopping time and resulting in even longer days of toil.