Belt Lacing

- PART OF:

- Lancashire textile industry material

- Made:

- 1900-1920 in United Kingdom

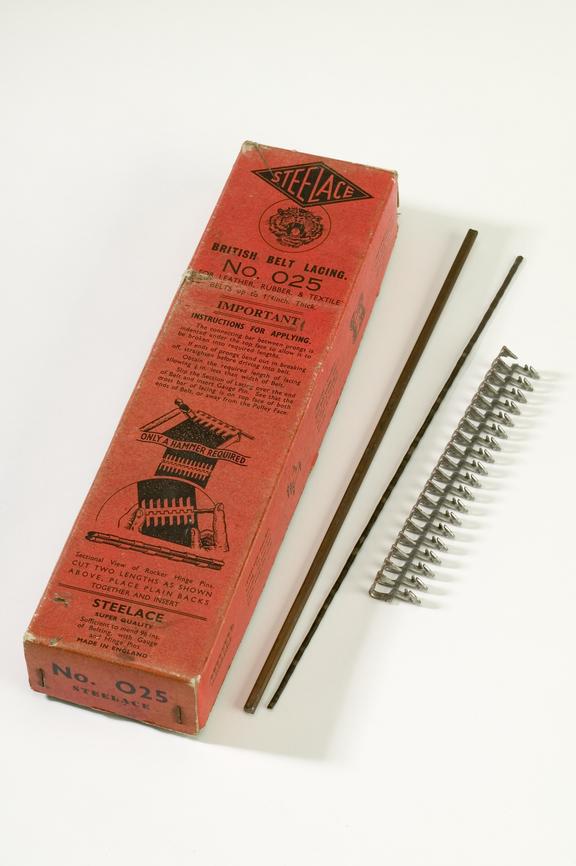

Box of leather belt lacing No 025, made by Steelace Manufacturing Company Limited.

In textile factories, the belts used to transmit power from a power source to the machinery

need to be bonded securely to create a continuous loop. This leather belt lacing provided a quick, simple, secure way to join the belting material.

The metal-toothed clasp was hammered to grip into the belt where they were to be bonded. The clasps are interlaced and connected by a wire rod. This system was used to join two pieces of leather, rubber or textile belting.

Line shafting, using belts, allowed a central source of power, such as a waterwheel, steam engine, or turbine, to power multiple machines at once. Using pullies, gears and belts, the power was transmitted, via the line shafting system, typically suspended from the ceiling, throughout the mill or factory.

Details

- Category:

- Textile Industry

- Object Number:

- Y2006.35.9

- Materials:

- cardboard, metal (unknown) and wood (unidentified)

- Measurements:

-

box: 44 mm x 83 mm x 312 mm,

- type:

- textiles equipment