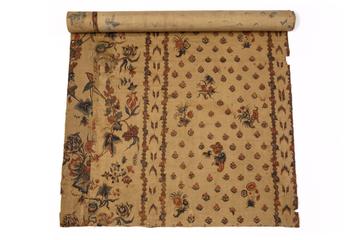

Five roller textile printing machine made by William Mather, Manchester, around 1850.

This 5 roller textile roller printing machine is representative of the mechanisation of textile printing which took place in Britain to meet the increasing demand for printed cloth. Before mechanisation, wooden blocks with patterns cut in relief and copper plates with engraved patterns were used to print cloth. Both methods were time consuming and the production methods could not keep up with the increasing demand for printed cloth. In 1785 in Preston, Joseph Bell developed and patented a cylinder printing machine. A copper roller was engraved from end to end with the pattern to be printed. As it revolved, it picked up dye and the cotton to be printed was then drawn over the cylinder. The printed fabric then moved through a series of steam dryers. Later developments meant multiple cylinders with different parts of the pattern and different colours could work on a single machine to produce complex printed designs. The development completely transformed the printing industry, increasing output, productivity and ways of working.