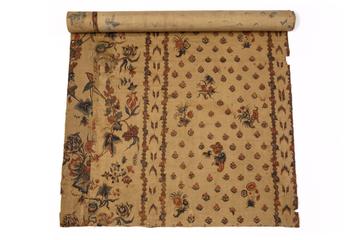

Cop tubing apparatus

- Made:

- 1900-1920

Large gauge cop tubing apparatus, manufactured by E. Jagger & Co. in Oldham, early 20th century.

This cop tubing apparatus is a hand operated device used by workers called doffers to load empty paper cops onto the spindles of spinning mules, ready for the yarn to be spun onto them.

Spinning mules worked in an intermittent process, twisting and then winding yarn onto paper cones called cops (they could also spin onto wooden pirns but these devices were designed for use with paper cops). Once the cops were full, the machine had to be stopped whilst the full cops were removed individually from the mule's spindles by hand and new, empty cops were loaded, in a process known as doffing. In 1857 a patent for cop tubing devices was taken out by Leopold Newton of Oldham, whose company commissioned other businesses to manufacture and sell these devices to the textiles industry.

These devices reduced the amount of time that the spinning mules were stationary to refill the cops, as they allowed multiple mule spindles to be replenished with empty cops at one time, therefore maximising productivity. In addition, whilst the spinning mule was operating, workers could prepare the cop tubing device with cops ready for loading, further increasing efficiency. Cop tubing devices also ensured that the cops were loaded on uniformly, as when the cops were loaded by hand the cops could be loaded at different heights which could cause issues with the mule.

Coping tubing devices came in different sizes to suit different types of spinning mules. This example is a large gauge device, which refers to the distance between the centre of the spindles on a mule, anad means it would have been used with a spinning mule spinning coarse yarn. It was less common than others types, possibly due to the fact that it had a trigger mechanism which was not easy to use.

Details

- Category:

- Textile Industry

- Object Number:

- 2020-451

- Materials:

- metal (unknown)

- Measurements:

-

overall: 270 mm x 740 mm x 300 mm,

- type:

- cop tubing apparatus