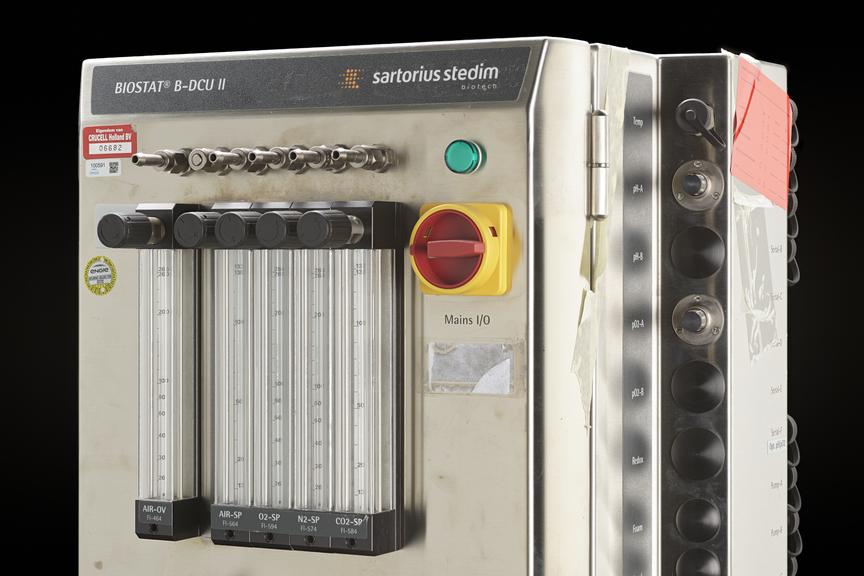

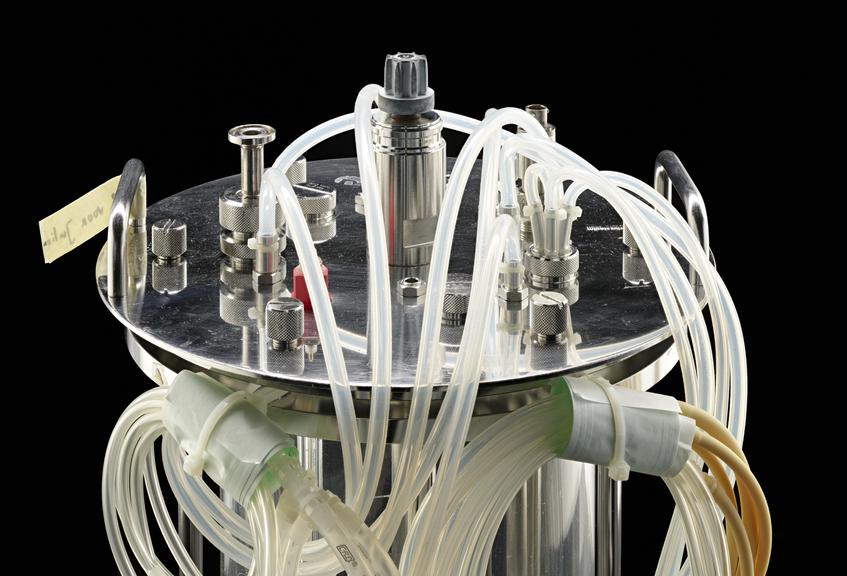

Control Panel for cell expansion bioreactor used in the production of the Janssen Johnson & Johnson COVID-19 vaccine

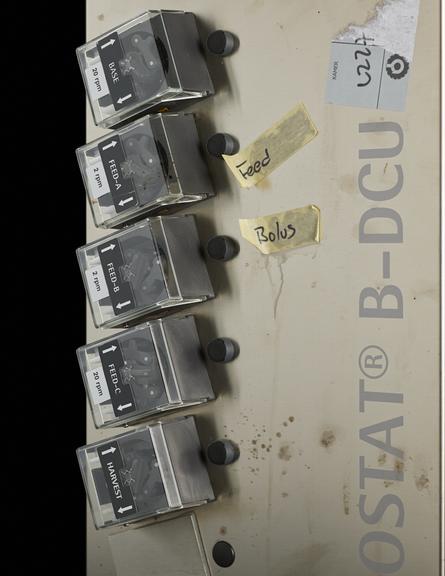

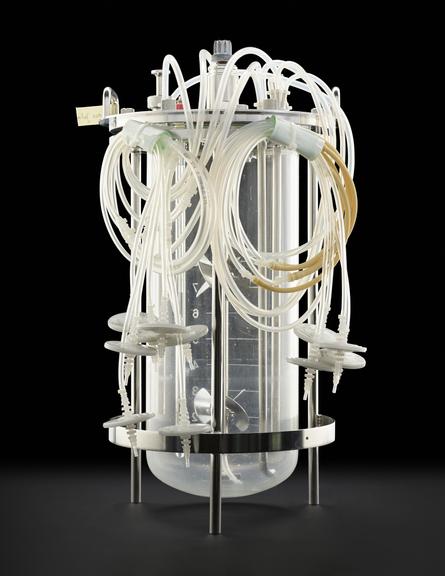

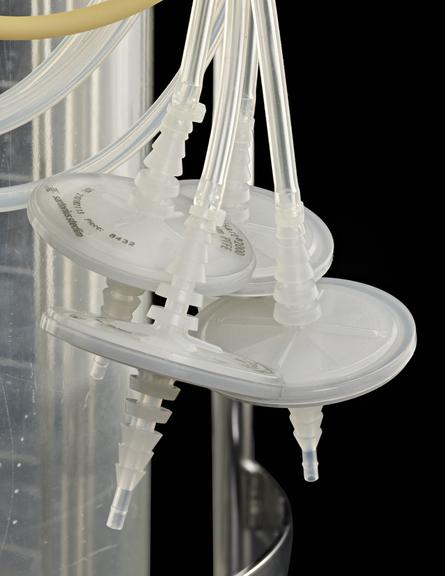

Biostat® B-DCU II control panel, used for as cell expansion bioreactor or as virus production bioreactor for the early production of the Janssen Johnson & Johnson COVID-19 vaccine, 2020-2021

More

This bioreactor was essential in the early production of the Janssen Johnson & Johnson COVID-19 vaccine to produce their vaccines for phase 1, 2 and 3 clinical trials and emergency use batches to start 50 litre vaccine production.

The vaccine uses a deactivated human common cold virus, known as an adenovirus, to deliver the genetic code for the coronavirus (SARS-CoV-2), spike protein. This is a protein on the SARS-CoV-2 virus which it needs to enter our cells. Later, if the person comes into contact with the COVID-19 virus, the person’s immune system will recognise the spike protein on the virus and be ready to defend the body against it. The adenoviruses are grown in the PER.C6 cell line, derived from human embryonic retinal cells. For 7 days the cells grown until there are sufficient cells to start the cell expansion process in another bioreactor which takes a further 10 days. Another 3 days are needed to cultivate the adenoviruses. The PER.C6 cells are filtered out and removed during vaccine manufacturing.

Drawing on decades long work, researchers at Beth Israel Deaconess Medical Center, worked with Janssen Vaccines, a subsidiary company of Johnson and Johson, to rapidly identify possible candidates for a COVID-19 vaccine in January 2020. After much testing the AD26.COV2.S candidate went into small scale production in Leiden, Netherlands, for further testing and clinical trials. Within 13 months, their single dose vaccine was approved for emergency use in the United States for over 18s in February 2021. In total ,103 countries approved the use of Johnson & Johnson’s vaccine, known by the brand name Jcovden.

- Measurements:

-

overall: 820 mm x 400 mm x 530 mm,

- Materials:

- metal (unknown) , plastic (unidentified) and glass

- Object Number:

- 2022-1077/1

- type:

- control panel

- Image ©

- The Board of Trustees of the Science Museum