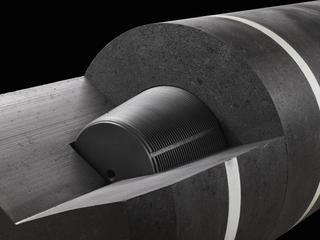

Original pilot Bessemer converter, 1865.

- Made:

- 1865 in Barrow-in-Furness

Original pilot Bessemer converter from which the first cast of steel was poured at the works of the Barrow Haematite Steel Company Ltd., Barrow-in-Furness, in May 1865

The Bessemer process of steelmaking was the first viable method of producing steel in large quantities. This converter was used at the Barrow Haematite Ironworks, set up by Henry Bessemer, for experiments in perfecting the process. Steel is iron containing a small amount of carbon, up to about 1.5%. Bessemer discovered that if air is blown through molten iron (which contains about 3% carbon) in a converter, some of the carbon would combine with oxygen in the air and be burnt out, reducing the carbon content. No extra fuel was required, because the carbon, oxidised during the blow, generated great heat. This made available large quantities of steel at a reasonable price, gradually replacing wrought iron. Bessemer faced technical challenges perfecting his steel-making process, particularly using it with iron ore containing a lot of phosphorus. However, modern steel making still relies on Basic Oxygen Steelmaking, which is derived from Bessemer’s original process.

Details

- Category:

- Metallurgy

- Object Number:

- 1959-186

- Materials:

- cast iron, refractory clay and wrought iron

- Measurements:

-

overall: 2600 mm x 3000 mm x 1600 mm, 1300 kg

- type:

- bessemer converter, steel and bessemer process

- credit:

- Killingbeck, W.