Ultrasonic flaw detector, 1956-1960.

- Made:

- 1959-1960

- maker:

- Kelvin and Hughes Limited

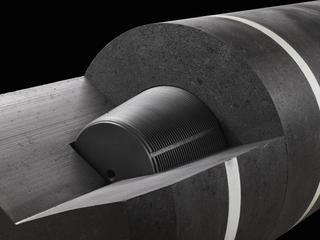

Ultrasonic Flaw detector by Kelvin and Hughes Ltd, 1959-1960

Ultrasonic flaw detection is an example of non-destructive testing of metal components for cracks and flaws.Non-destructive testing is the examination of components by methods that do not change the surface or centre of the component.There are various techniques involving magnetic crack detection and die penetrant methods for surface cracks, whilst X-rays, gamma-rays and ultrasonic testing reveal internal flaws.

Details

- Category:

- Metallurgy

- Object Number:

- 1960-194

- type:

- ultrasonics and testing equipment

- credit:

- British Iron and Steel Federation