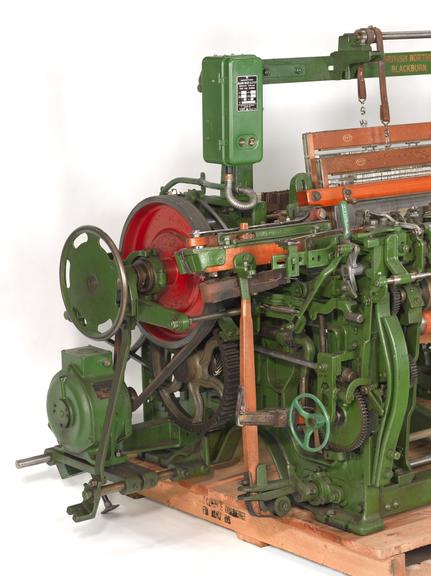

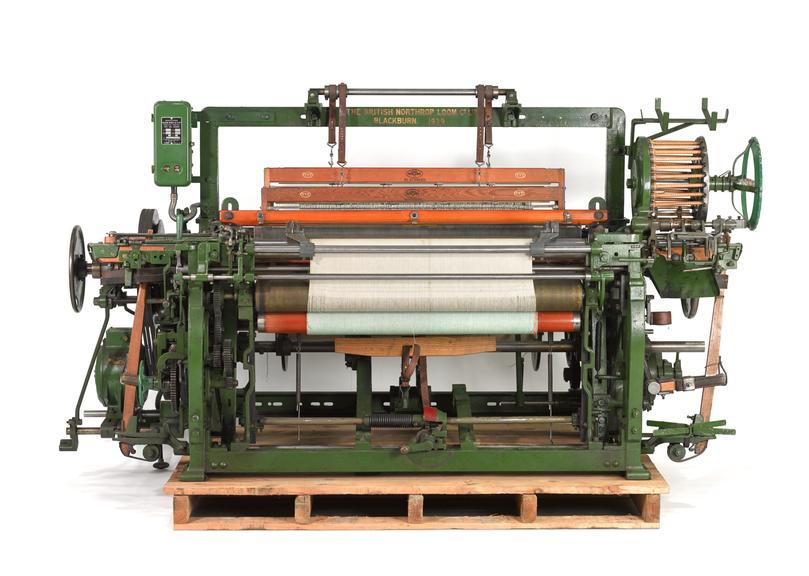

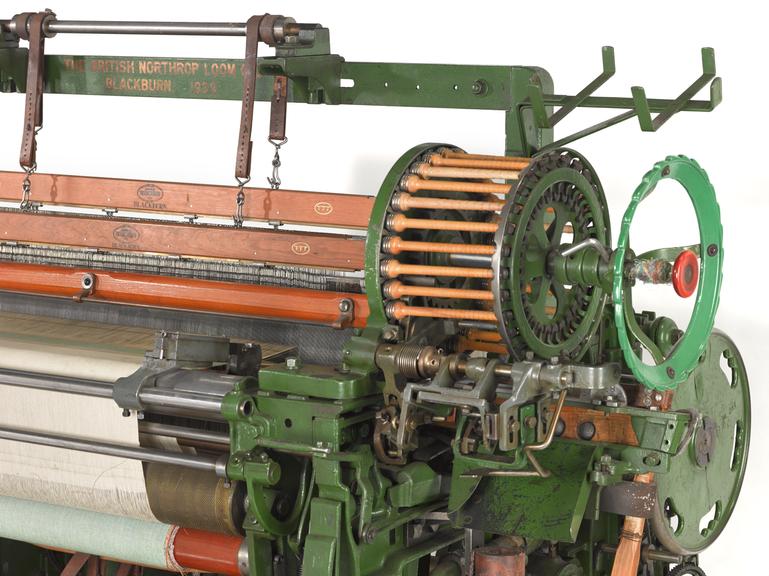

Northrop single-shuttle 'S' loom with automatic bobbin insertion, 1939. Comprised of loom, bobbin box, 32 bobbins and 2 shuttles.

The successful invention by James H. Northrop between the years 1889 - 1894 of a method of automatically replenishing the weft is the most important achievement in the history of the loom since the power loom was invented in the 18th century.

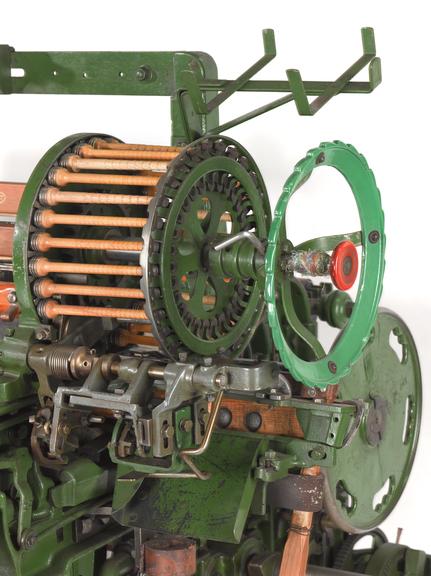

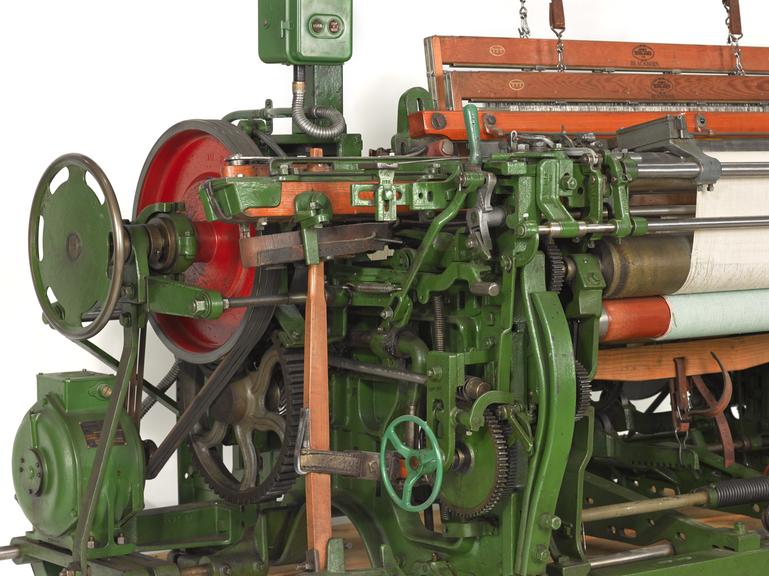

In this Northrop loom, manufactured in 1939, whenever the shuttle runs short of weft, a full bobbin from the rotary battery is automatically inserted. A feeler passes through a hole in the left-hand shuttle box, when the shuttle is momentarily stationary between picks, and if it finds the bobbin nearly empty, actuates the changeover mechanism, which operates when the shuttle next reaches the right-hand box. A thread cutter cuts the weft off the nearly empty bobbin just at the moment when it is pressed out of the shuttle and retains the weft which remains outside the cloth until after it has been cut away from the selvedge by a temple thread cutter.

As this type of loom requires only occasional attention, a weaver can look after 24 looms or even more. To make this possible, it is necessary for the loom to stop automatically should a warp thread break so that it can be repaired before the cloth is ruined. This loom is equipped with a mechanical warp-stop motion. Each warp thread passes through a drop wire, and should it break, the drop wire falls into slots in three bars, the middle one of which oscillates from side to side. The drop wire by preventing this motion, stops the loom. Other automatic devices stop the loom if the weft should break or if the shuttle should fail to go right home in either shuttle box.