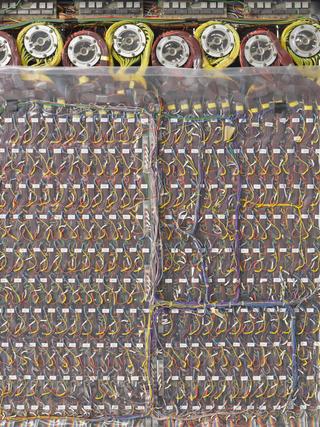

Two photographs and one diagram, Lucas automatic sounding machine for gauging depth of the sea floor

Two photographs and one diagram, Lucas automatic sounding machine. The Lucas sounding machine paid out wire in order to gauge the depth of the sea floor, and was invented by Francis Robert Lucas, c.1878.

Submarine cable laying operations provided an impetus for the study of the ocean floor. It was not only important to obtain accurate measurements of the depth of the sea bed, but also samples of the ground over which cables were to be laid, and sea bed temperatures (which affected the insulating properties of the gutta percha insulation of cables, and thus signal transmission times). Such expeditions resulted in innovation in the methods used for sounding and sampling.

While early sounding devices consisted of weights attached to hemp ropes, the accuracy and ease of taking observations was improved by replacing rope with wire line. Wire took up much less space on board, a benefit especially for longer surveying expeditions and voyages. British physicist William Thomson and the American Lieutenant-Commander Charles Dwight Sigsbee both devised machines that allowed wire to be paid out over a series of wheels with resistance applied so that it was easy to determine when the sounder reached bottom.

As a young man Lucas had been involved in the laying of the first transatlantic telegraph cable aboard the Great Eastern. His sounding machine, a simpler version of Sigsbee’s, was first tested by the Hydrographic Office on the British Arctic Expedition of 1878-1879. It was used about HMS Alert, commanded by Captain George Nares.

Lucas became Chief Engineer to the Telegraph Construction and Maintenance Company and saw his machine become standard on most British cable ships and naval surveying vessels. It continued in use in modified forms until the 1960s.