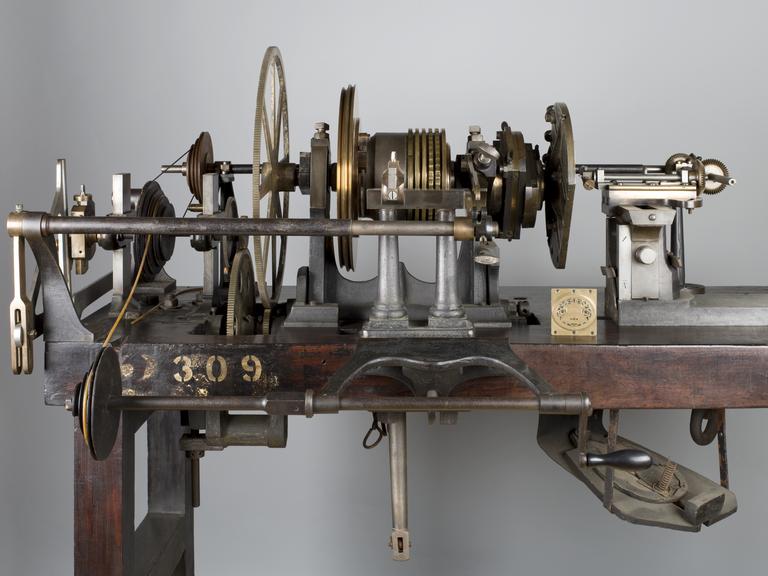

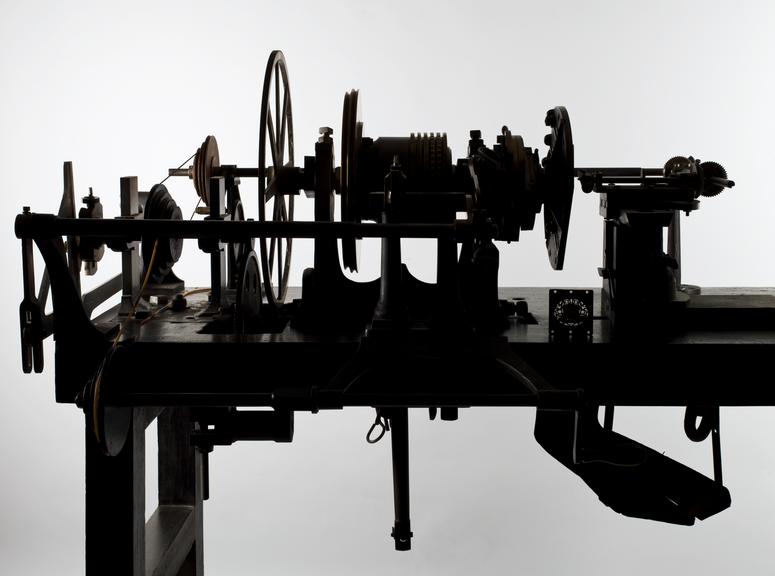

Rose engine lathe used to manufacture compound printing plates, built by Bryan Donkin, Bermondsey, London, 1820.

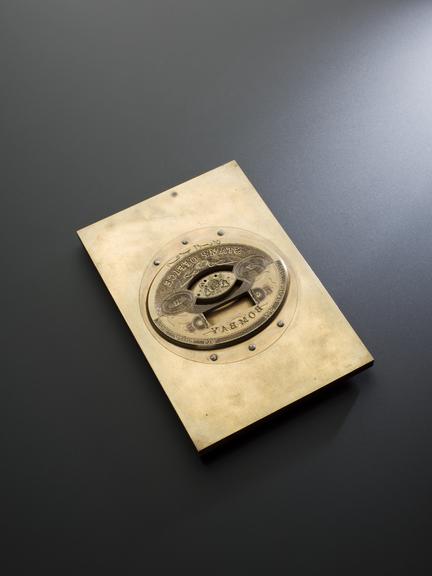

Sir William Congreve patented a process known as compound-plate printing in 1821, and the printing plates were engraved using this machine. It was devised primarily as a means of preventing forgery – from 1797 until 1821 Britain depended solely on paper currency, and in the decade to 1820 detected counterfeiting cases rose by more than 500%. Compound printing became widely used for producing duty stamps, postage stamps and much else from the 1820s onwards - but not for manufacturing banknotes, where a combination of techniques which also included compound printing, were applied.

Congreve’s concept was completely new, and he gave the practical project of making it work to Bryan Donkin. The process consists of highly detailed two-colour printing. This was done using a printing plate comprising two intricate and interlocking parts, an upper part fitting through appropriately-shaped apertures in the lower part. The two parts were separated vertically so that two different colour inks could be applied (one to each) and then they were brought together and the impression made on paper. Most importantly, the detail engraved on the two-part plate was made while they were fitted together, so any potential forgers were faced with the near-impossible challenge of not only reproducing the complex mathematical shapes generated by the machine, but also duplicating the colour changes for each individual line exactly.

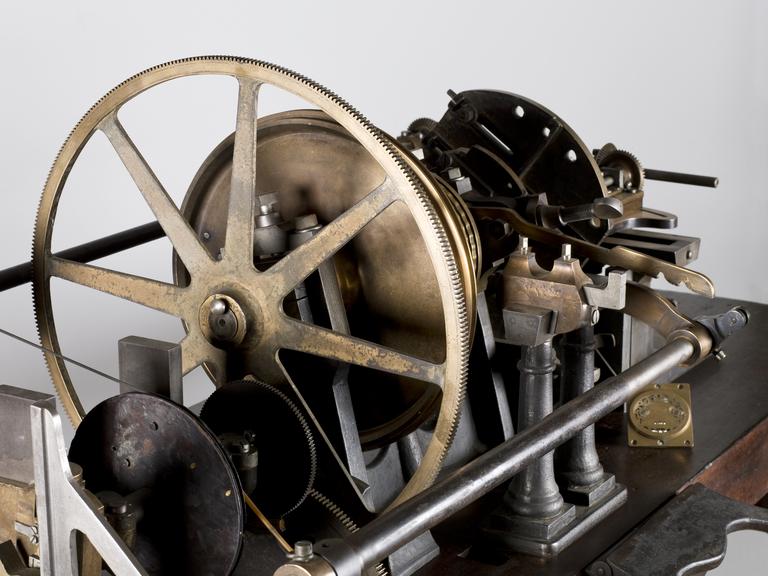

Unlike other ornamental lathes, the lathe has neither tail stock nor moving carriage, the small amount of necessary longitudinal movement being achieved from a compound slide mounted on the cross slide. The main spindle carries a gang of only five rose cams, which were used merely for outline patterns. The more usual way of producing wave patterns on this lathe is to disconnect the rubber from the roses and connect in its place a rocking lever system: mounted on the main spindle beyond the roses and drive pulley is a 360—toothed spur gear which, through an open gear train, rotates an adjustable cam (or eccentric) situated at the far left hand corner of the lathe. This in turn rocks a lever system, which is connected back to the main spindle.

Both the eccentric cam and the cross slide have fine adjustment screws and measuring scales with which to vary the depth of the wave, whilst change wheels give gear ratios to generate any number of waves from four to sixty per revolution. Another strange (if not unique) feature of the lathe is a bevel drive from the rear of the machine which, when engaged, rotates the engraving tool holder, the resulting circular path of the tool tip being varied by a tiny counterslide.