Steam locomotive, entitled Evening Star

1960

1960

1936

1862

1804-1807

1855

1884

1927

1925

1857

1804-1807

1874-1880

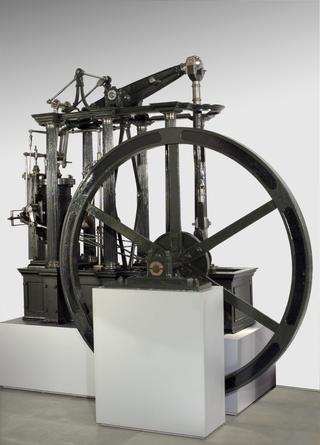

1740

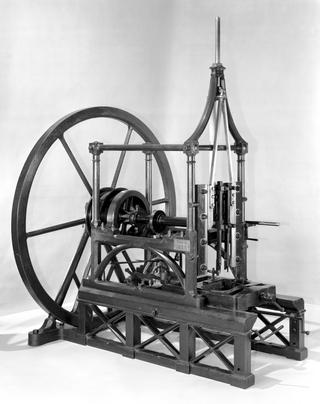

1821

1843-1857

1878

1897

1881-1919

1879-1888

1921

1926

1874-1880

1853-1891

1925

1921

circa 1740

1929

1954

1820-40

1886

1941

1947

1865

1889

1917-1958

1817

1862

1804-1807

1898

1892

1820-1840

1916

1804-1807

1871

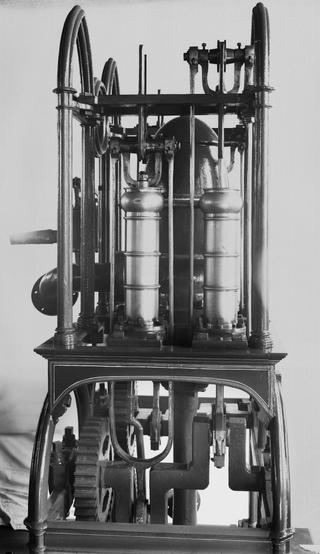

circa 1800

circa 1850