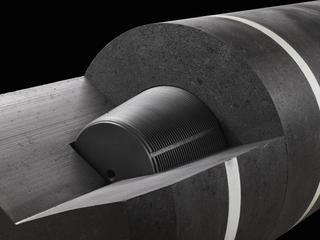

Jet Engine Turbine Blade made of Nickel Alloy

- maker:

- Access e.V. TechCenter

Turbine blade made of nickel alloy, developed by ACCESS e.V. TechCenter, Aachen, Germany, 2007.

Nickel alloys have been conventionally used in aircraft and engines. They are strong, tough, and resistant to corrosion.

Titanium aluminide is an alloy used in aircraft, jet engines and cars since around 2000. It is lightweight and highly resistant to oxidation and corrosion even at high temperatures.

Titanium aluminide is around 50% lighter than nickel alloys while still meeting the requirements for strength, resistance and durability at the high temperatures of a jet engine. Using lighter materials improves fuel efficiency of aircraft, thus reducing emissions, and so significant research is being undertaken to minimise the weight of materials used while maintaining performance.

Access e.V. TechCenter is a research and development institute based in Aachen, Germany. They specialise in material science and engineering, especially metals, developing new metallic materials such as these intermetallic alloys, and casting processes.

Details

- Category:

- Metallurgy

- Object Number:

- 2022-1364

- Materials:

- nickel silver (nickel, copper, zinc alloy)

- Measurements:

-

overall: 240 mm x 40 mm x 20 mm,

- type:

- nickel turbine blade

- credit:

- Access e.V. TechCenter