Eurostar 3000 satellite, 2000

2000

2000

1993

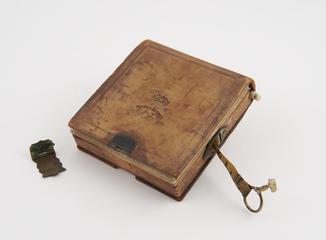

1878

1980

1920-1939

1980

2012-2013

October 2011

2021

2012-2013

2012-2013

2012-2013

2012-2013

1973

1962-1964

1962-1964

2004-2005

1997-2007

1997-2007

1984

1973

1989

2007

2007

2017

2015

1997-2007

1851-1900

2005-2006; 2014

2012-2013

2012-2013

2012-2013

2012-2013

2012-2013

2012-2013

2008

1997-2007

1846-1860

2010

2021

2014