Brown & Sharpe automatic lathe

circa 1897

Treadle operated ornamental lathe

1817-1823

Lathe made by Alfred Herbert Ltd

Lathe Made by Kendal & Gent

Wheel Lathe, Made by Hulse & Co.

1890-1930

Metal Turning Lathe

Smith & Coventry Capstan Lathe

circa 1890

Whitworth Lathe No. 626

1880

Magnetic lathe chuck

Wooden bed lathe and associated tools, used by Pennington Mill Co. Ltd

1800-1850

Watchmaker's lathe used by James Lovelock

Lathe, made by Carver

Lathe no. 1254

1822

Double-bed lathe, made by William Ryder Son & Co.

Lathe no. 2326

1877

J. Whitworth & Co. Lathe

circa 1876

Whitworth Lathe No. 4

1841

Lathe by J. Whitworth & Co, c. 1870

1870

Lathe, London & South Western Railway

1890-1900

Weight- driven recording lathe for use with Decca ffrr cutter head.

Herbert 5" lathe

Lathe

Old wooden bed Millwright's lathe

Screw thread correcting lathe

Centre lathe with foot motor

c. 1900

Turner's Lathe (for pottery) complete with treadle

Scale model of George Stephenson's lathe and power wheel

1963

Modelmaker's centre lathe

1904-1996

Lathe

1790-1819

Bench lathe by Wilhelm von Pittler A.G., model B

Lead screw correcting lathe and accessories by Armstrong Whitworth and Co

1904

Triple Prismatic Lathe by Johnson Jex

1817-1822

Myford ML7 lathe; 3 jaw and 4 jaw chucks

Vertical Capstan or Turret Lathe Boring Machine of moderate size

1942-1946

Dahlegren lathe with countershaft, cutters and specimens of work and accessories

1891

Parmeko recording lathe

Footlathe by Henry Maudslay. Footwheel and shaft

Ward 2A capstan lathe

Lathe bench, bar lathe on top, footwheel and treadle below.

1810

Colchester Triumph 2000 lathe

1971

Herbert centre lathe

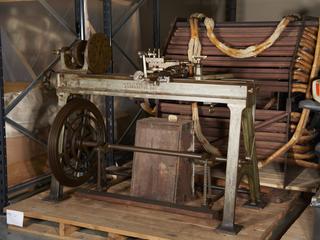

Early pittler capstan lathe / turret lathe

circa 1892